From Experience-Driven to Intelligent Decision-Making: The AI Evolution of Inventory Management

Layer upon layer of approval processes, warehouses overflowing with materials, yet production lines stall due to parts shortages. Best-selling items suddenly sell out, while replenishment orders are delayed circulating between departments—the profits of many enterprises are quietly eroded by these "hidden costs."

For manufacturing, trading, and retail enterprises that rely on their supply chains, traditional inventory management often entails heavy manual stock-taking, tedious document verification, and fuzzy decision-making based on experience. Decision-making lag, data silos, and slow response have become core pain points hindering agile business development.

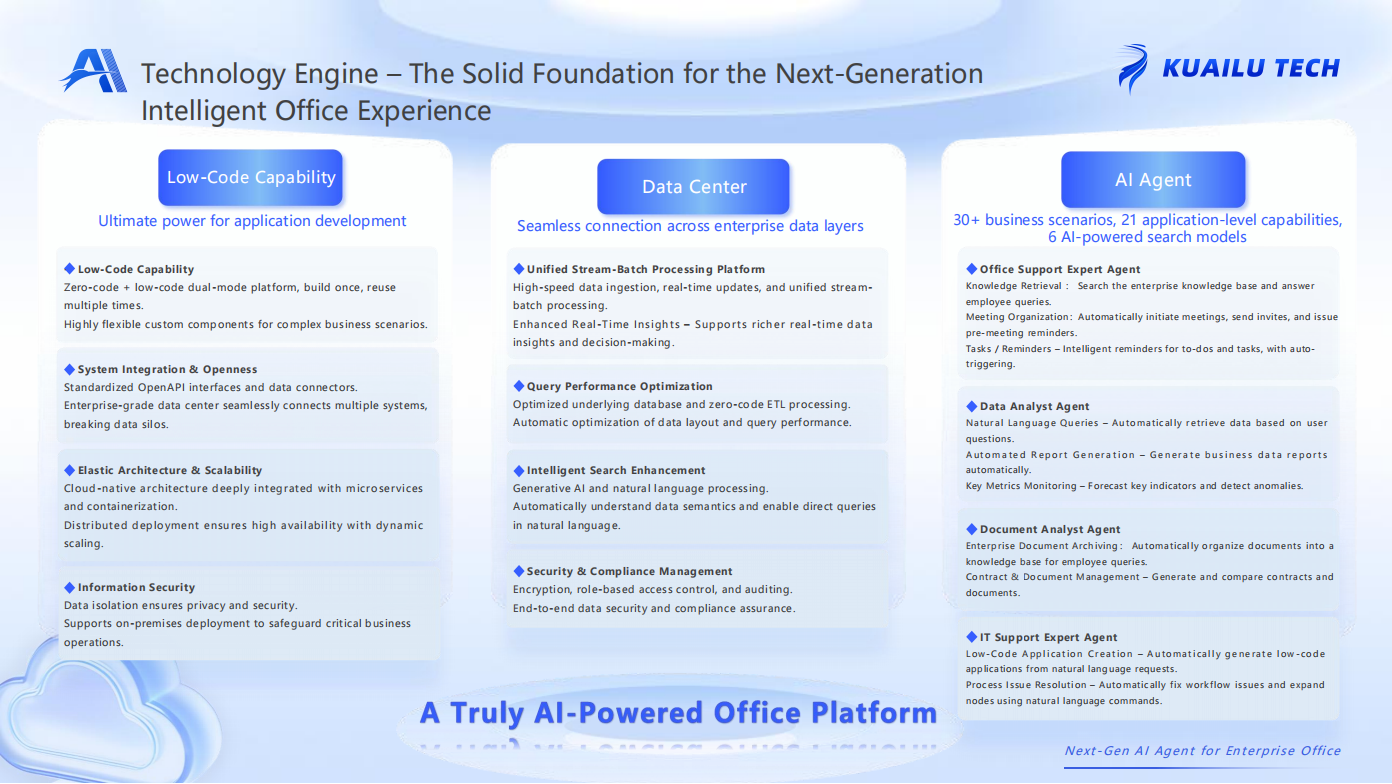

Today, AI technology centered on natural language interaction and intelligent decision-making is bringing transformative changes to inventory management. The Kuailu Cloud AI Intelligent Office System launched by Kuailu Tech, by deeply integrating large AI model capabilities with business processes, marks the official transition of enterprise management from "process-driven" to a new stage of "data and AI dual-driven." Its embedded AI capabilities, such as intelligent procurement suggestions and dynamic sales optimization, allow the system to move beyond simple automation into the realm of predictive and prescriptive operations.

From Experience to Intelligence

The inventory management of enterprises has roughly undergone three stages, with the core being the evolution of decision-making basis and response speed.

The early stage relied on manual ledger books and human experience, with high decision-making risks and responses measured in "weeks" or even "months." With the proliferation of ERP systems, it entered the informatization stage driven by process solidification. Data became electronic, and response speed improved to the "day" level, but data fragmentation between systems created new information islands.

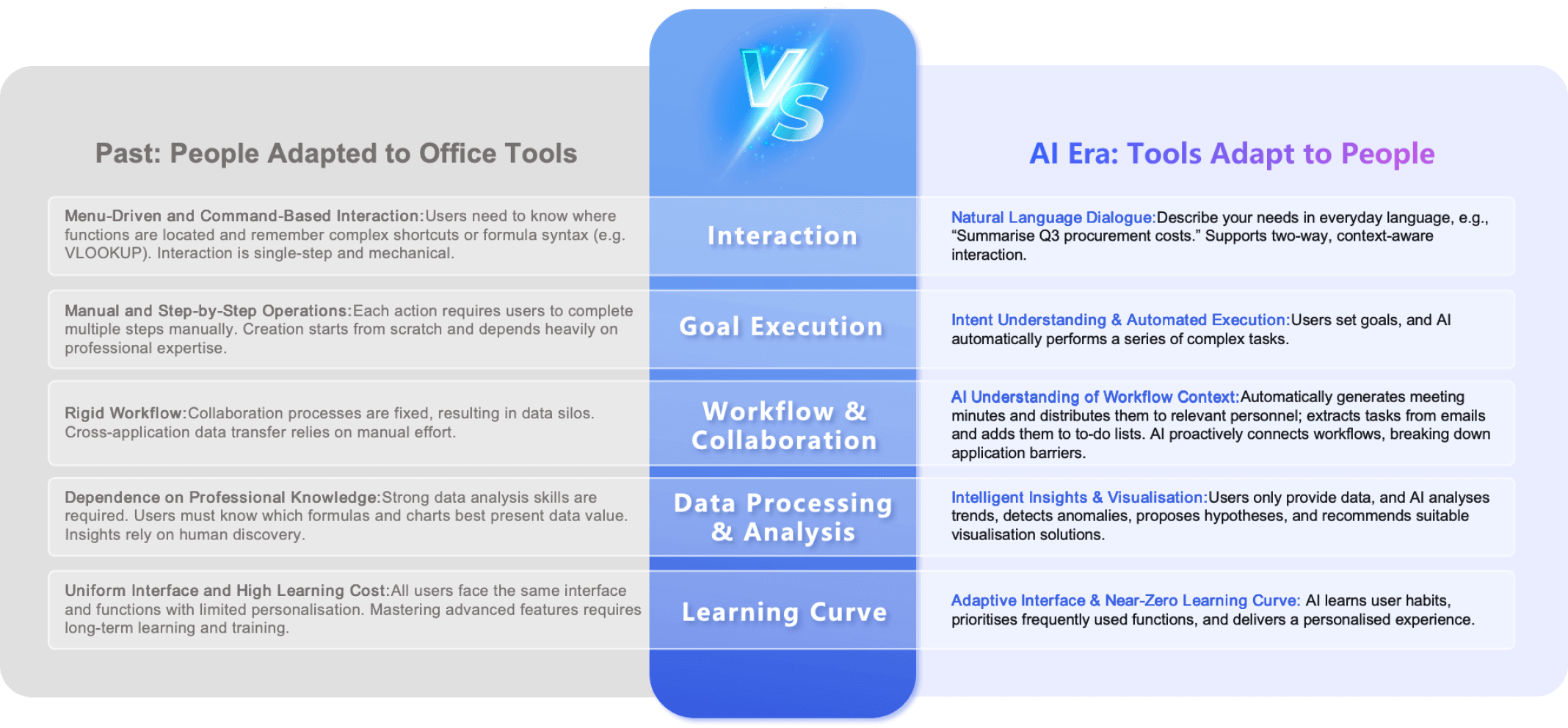

Currently, the industry is moving towards a new, From“People Adapting to Office Tools”to“Tools Adapting to People”. Its core characteristic is that the system can actively perceive business changes, predict future trends, and automatically execute optimal decisions. In this stage, response speed is "real-time." For example, by leveraging predictive analytics, the system can sense demand fluctuations in real-time and automatically trigger purchase, transfer, or production suggestions.

This aligns with the vision of creating a "digital twin" of the supply chain for smarter orchestration.

AI Empowerment: Reconstructing Core Scenarios of Inventory Management

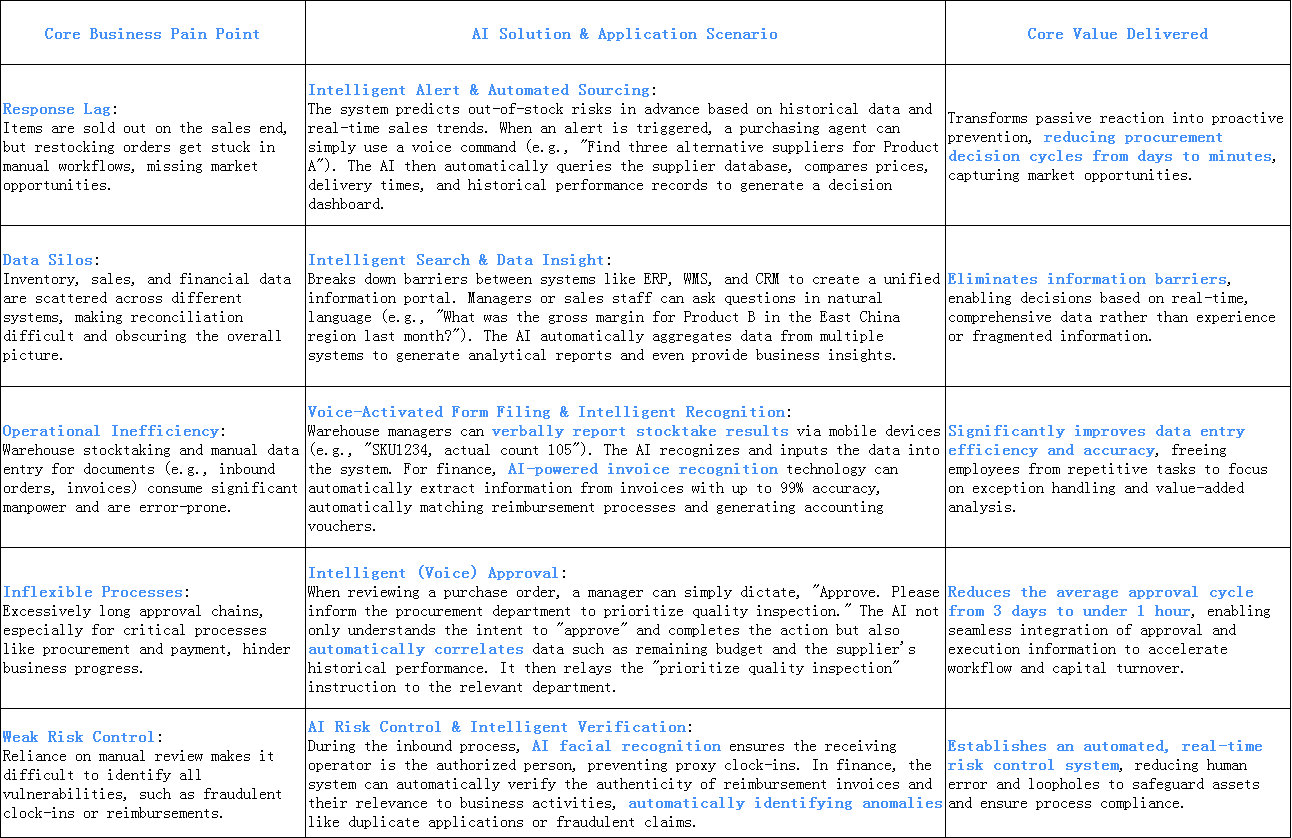

AI is not an abstract concept; it can already be deeply embedded into various specific aspects of inventory management, directly addressing the most critical business pain points.

1.Intelligent Procurement & Replenishment: AI algorithms analyze historical sales data, seasonality, market trends, and lead times to generate accurate demand forecasts. This enables proactive, optimized purchase orders and automatic replenishment suggestions, minimizing both stockouts and excess inventory. This transforms procurement from a reactive function into a strategic, predictive one.

2.Smart Warehouse Management: AI-powered systems can optimize warehouse layouts and picking routes. Furthermore, they can automate inventory tracking and reconciliation, significantly reducing manual counting errors and saving time. Some advanced systems utilize computer vision for goods identification and inventory status verification.

3.Sales & Demand Forecasting: AI goes beyond simple historical analysis. It can process vast amounts of internal and external data, including market sentiment and competitor activity, to provide highly accurate sales forecasts. This allows for dynamic pricing strategies and precise production planning, ensuring businesses can meet demand efficiently.

4.Breaking Down Data Silos: A key advantage of platforms like Kuailu Cloud is their ability to integrate data from disparate systems (ERP, WMS, CRM). AI acts as a unifying layer, providing a single source of truth. Users can query this unified data using natural language (e.g., "Show me the profitability of Product X in the last quarter"), and the AI generates insights and reports, enabling data-driven decision-making across procurement, inventory, and sales teams.

5.Automation of Repetitive Tasks: AI automates routine but time-consuming tasks such as data entry from invoices, purchase order generation, and basic customer communication for order status. This frees up human employees to focus on higher-value activities like supplier relationship management and strategic analysis.

From Intelligent Tools to "Digital Twins"

The application of AI in inventory management will go beyond point-based efficiency improvements and may trigger deeper organizational changes. A compelling concept is the "Digital Twin"—where AI not only assists humans but can also simulate the professional behavior of specific roles and create a virtual model of the entire supply chain.

For example, a "Procurement Digital Twin" can monitor global commodity price fluctuations, supply chain disruptions, and order delivery dynamics 24/7. When predicting a shortage risk for a key material, it can automatically simulate multiple supply assurance scenarios (e.g., evaluating backup suppliers, suggesting safety stock levels) and present risk-assessed recommendations to managers. Similarly,

an "Inventory Digital Twin" can continuously learn and optimize stock levels across all warehouses. This evolution means the inventory management system transforms from a passive record-keeping tool into a proactive, intelligent entity capable of simulation, continuous optimization, and collaborative operation.

How to Move Towards Intelligent Inventory Management

1.Diagnose Pain Points and Prioritize Scenarios: Avoid pursuing an overly broad solution. First, identify the most painful and time-consuming aspects of your current operations, such as monthly stock-taking, supplier negotiation, or demand forecasting. Use these specific scenarios as the primary entry points for AI implementation.

2.Evaluate Technology Based on Practical Application: When evaluating potential system vendors, focus on the practical application of their AI capabilities in real-world scenarios, not just technical specifications. Investigate whether their AI functions, such as predictive analytics or natural language processing, directly address your diagnosed pain points.

3.Choose an Open and User-Friendly Platform: Prioritize platforms like Kuailu Cloud that offer low-code or no-code capabilities and open APIs. This ensures that as your business evolves, your team can quickly adapt workflows and integrate new tools without constant reliance on developers, allowing the system to truly "grow" with the business.

4.Start with a Focused Pilot: Select a specific product line, category, or regional warehouse as a pilot for intelligent upgrade. For example, first implement AI-driven demand forecasting or intelligent replenishment alerts for that segment. After achieving quantifiable results (e.g., reduced stock-outs, lower carrying costs), use the case study to justify and guide a broader rollout.

5:.Prepare Your Data Foundation: Simultaneously, begin organizing, cleaning, and standardizing your core data (products, suppliers, customers, and transaction history). High-quality, structured data is essential "fuel" for effective AI analysis and reliable outcomes.

The essence of business competition is efficiency. When inventory management evolves from hindsight reporting to foresighted intelligent orchestration, enterprises gain not only cost reduction and efficiency improvement but also the core resilience to remain agile and operate steadily in an uncertain market.

The ultimate goal of technology is to make tools invisible and value prominent. Let machines handle repetition, and let humans focus on creation. AI-driven intelligent inventory management, as exemplified by platforms integrating these capabilities, is turning this vision into the daily operational reality for forward-thinking enterprises.