Kuailu Tech Helps Hong Kong Veteran Enterprise Show Win Textiles Weave a New "Intelligent Manufacturing" Blueprint!

"Thousands handling yarn, tens of thousands weaving cloth" once aptly described the traditional labor-intensive textile industry. In today's fast-paced, globalized textile sector, a company's competitiveness is often determined by its mastery over orders, production, processing, inventory, and data. When traditional management models collide with the digital wave, the choice is between stagnation and proactive transformation.

Today, we examine how Show Win Textiles, a prominent Hong Kong-based textile enterprise, partnered with Kuailu Tech to embark on a new chapter of intelligent transformation.

01 Enterprise Challenges & Needs

I. Corporate Background: A Typical Global Textile Enterprise

Show Win Textiles is a premier fabric manufacturing and sales company, headquartered in Hong Kong with a global footprint.

Its operational structure is as follows:

• Hong Kong Headquarters: Core teams for sales, marketing, and development engage directly with overseas clients, managing and coordinating factory production and delivery.

• Mainland China Factories: Handle the complete fabric production and processing cycle, serving as influential manufacturers within the industry.

• Overseas Operations: Owns multiple dyeing and processing facilities abroad and maintains a network of supply chain partners across various international locations.

• Complex Workflow: The process spans order receipt, sample development, yarn procurement, weaving, dyeing, quality inspection, and final shipment, involving extended chains, numerous stages, and complex inter-departmental coordination.

II. Intelligent Upgrade Requirements for the Future

As the textile industry advances toward globalization and smart manufacturing, digitalization demands continue to escalate. As a globally positioned enterprise, Show Win Textiles aims to "respond to customer needs with greater precision and ensure order delivery with higher efficiency."

Consequently, management is not content with the status quo. They recognize that securing industry leadership for the next decade requires building new competitive advantages through data integration, automation, and AI collaboration. Leveraging digital tools is essential to enhance end-to-end operational synergy and decision-making accuracy, thereby better serving a growing global clientele.

1.Enhance Business Management EfficiencyLeadership seeks an integrated data dashboard to provide real-time, consistent, and accurate information across fabric development, orders, procurement, weaving, dyeing, processing, delivery, and invoicing. This would liberate personnel from repetitive "search-and-verify" tasks, allowing them to focus on higher-value customer service activities.

2.Upgrade to a Digital AI SystemThe limitations of legacy systems become apparent with expanding global operations and the need for real-time cost-profit analytics. Management intends to implement a more intelligent platform that integrates ERP and OA systems. This will enable end-to-end cost and profit visibility for each order—from raw yarn materials through weaving, dyeing, processing, and shipping—supporting more agile and precise business decisions.

3.Accelerate Global Data UnificationBusiness expansion across Hong Kong, Mainland China, and Southeast Asia has led to data fragmentation across disparate tools, demanding superior collaboration. The company aims to establish a unified, reliable data hub to enable real-time synchronization and seamless collaboration of business data from all global points, thereby boosting overall operational efficiency and cross-team responsiveness.

4.Refine Warehouse ManagementManaging a diverse product range across numerous domestic and international warehouses presents challenges in handling multi-category, multi-batch, and multi-warehouse complexities. Through system enhancement, the company targets precise inventory control and intelligent querying based on multiple dimensions like fabric type, process, color, and weight, providing data-driven support for supply chain optimization.

5.Build a More Secure Information ArchitectureWith business growth, management acknowledges the necessity for a robust data permissions and security framework. This ensures core commercial information—such as costs, quotations, and profit margins—circulates strictly within authorized boundaries. It also addresses compliance management and risk mitigation requirements across multiple regions and departments, balancing collaboration efficiency with information security.

These pain points are not unique to Show Win Textiles but represent common challenges confronting the entire textile manufacturing sector during its digital upgrade journey.

02 The Kuailu Solution

Tailored for Textile Enterprise Processes

Addressing the specific operational scenarios and pressing needs of the traditional textile industry, Kuailu Tech does not offer rigid, off-the-shelf software. Instead, leveraging the Kuailu Cloud integrated AI-powered office platform, it delivers a customized digital transformation blueprint for the integration of manufacturing and trade in textile enterprises, designed to enhance production efficiency and reduce labor costs.

I. Building an End-to-End Integrated Management Platform for Textile Operations

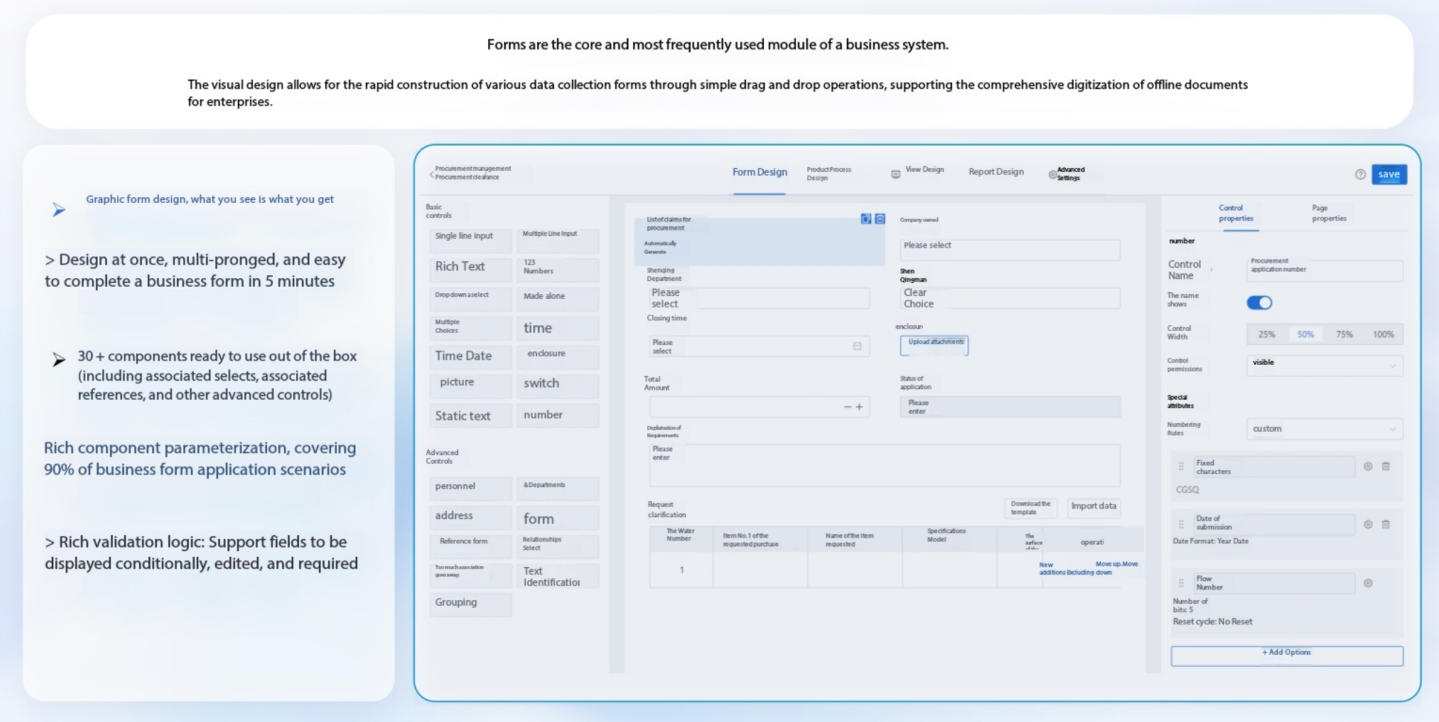

- ◆ A low-code platform constructs a tailored data dashboard for the complete textile workflow, consolidating end-to-end business data.

- ◆ AI agents automatically capture data from each process stage, supporting real-time order progress tracking on both PC and mobile interfaces.

- ◆ Interconnected data centers provide a unified visualization dashboard. AI-assisted tools enable business forecasting and milestone alerts based on underlying data, realizing "information finding people."

- ◆ Utilizing Kuailu Cloud's process management capabilities (a universal service), standardized control and progress tracking across the entire workflow are achieved.

A Single Dashboard for Holistic Management: Executives, merchandisers, shipping staff, weaving mills, dyeing factories, and sales personnel can view real-time order progress, production status, and factory data on PC or mobile devices, constructing a "fully visual digital factory."

II. Kuailu AI Agents Enable Operational Digitalization

◆ AI agents drive operational digital transformation, encompassing all scenarios from cost accounting to financial analysis.

◆ Centered on an accounting engine module, business-finance integration is realized, ensuring seamless connectivity between operational and financial data. Business changes synchronize with finance in real-time, guaranteeing ledger consistency and alignment with physical stock.

◆ Supports AI-powered comparative analysis (year-on-year, month-on-month), delivers inventory turnover analysis and precise cost accounting, integrates inbound/outbound and financial data, and automatically computes actual profit.

◆ Combines financial and inventory management functions, resolving data silos inherent in legacy systems and enabling real-time visibility of operational data.

◆ The data center dynamically links PI/PO/inspection orders, yarn procurement, weaving/dyeing/processing data, and delivery information; it automatically calculates costs, sales revenue, and profit, providing immediate clarity on business performance.

III. Multi-System, Multi-Department, Cross-Region Data Integration

◆ Establishes a unified data platform, interfacing with diverse systems across domestic and international regions to enable synchronized data sharing across sales, factories, procurement, merchandising, and finance departments.

◆ Features built-in AI data import functionality, supporting intelligent recognition and batch import of raw data from various formats (e.g., Excel files, documents), eliminating need for manual, point-to-point integration.

◆ The Kuailu Cloud process management module eradicates paper-based approval workflows, enabling digital approval routing. Executive signatures are automatically synchronized and circulated, significantly improving approval efficiency.

◆ Globally deployable via SaaS architecture, it employs low-code customizable workflows (GBPM) to create adaptable forms, breaking down data barriers between heterogeneous systems.

◆ Data from Hong Kong, Mainland China, and overseas operations is fully integrated; documents such as Invoices and Packing Lists are processed automatically, reducing tedious manual entry and verification time.

IV. Kuailu Inventory Module for Enhanced Warehouse Data Accuracy

◆ The core inventory management module supports unified warehouse control. Combined with robust data center integration, it facilitates rapid real-time synchronization and updates of warehouse data across multiple global locations.

◆ The intelligent warehouse platform connects inventory data for comprehensive integration, supporting multi-dimensional precise queries covering samples, yarn, greige fabric, and finished products.

◆ Enables integration with heterogeneous systems and allows custom form configuration to accommodate regional warehouse management variances, meeting the need for unified control across multiple sites.

◆ Provides online querying of domestic and international factory data based on dimensions like lot numbers and weight, achieving digital management of yarn, greige fabric, and finished goods inventories. Inventory data updates automatically in real-time, drastically improving accuracy.

V. Data Permission Security Management for Streamlined Approvals

◆ Implements a refined permission management system based on the RBAC (Role-Based Access Control) model: access rights are assigned by role, department, and region, ensuring sensitive data isolation—preventing both unauthorized access and oversight.

◆ Dual-layer data isolation: Supports menu-level permission control (hiding modules from unauthorized users) and data-level permission control (e.g., executives view costs, merchandisers see only progress).

◆ Fully digitalized approval workflows: Executive signatures are automatically routed and synchronized; sensitive operations are logged and traceable. Electronic signature approval processes eliminate paper-based methods, with signatures auto-flowing to each relevant stage.

◆ Enables precise isolation of sensitive data: Access can be restricted to designated personnel (e.g., for sales prices, yarn costs, profits). The electronic signature approval process eradicates paper trails, with executive signatures automatically propagating through all required steps.

Implementation Results: Data-Driven Evidence of Intelligent Transformation

Following deployment of the Kuailu solution in the textile enterprise:

◆ Process Efficiency Improved: 24/7 digital management of the entire workflow increased on-time order delivery rate by 25%, and boosted cross-department/cross-region operational efficiency by 40%.

◆ Labor Costs Reduced: Order processing time decreased by 80%, manual error rates were significantly lowered, and the order fulfillment rate rose by 13%.

◆ Efficient Operational Management: Costs, profits, and sales revenue became transparent. Real-time BI reporting enabled data-driven decision-making, enhancing market responsiveness.

◆ Precise Data Control: Inventory accuracy climbed to 97%, inventory counting time was reduced by 65%, and historical order data became instantly accessible.

03 Why Choose Kuailu Cloud?

Kuailu delivers more than a generic toolset—it provides a solution deeply attuned to textile operations, simultaneously tackling the industry's three core challenges: data silos, process inefficiency, and cross-domain collaboration. It genuinely achieves real-time synchronization of data from multiple global factories, facilitates division of labor and cooperation, and enables comprehensive end-to-end process management.

The future of the textile industry belongs to enterprises capable of "weaving" efficiency from data. Kuailu Tech is dedicated to becoming the most trusted AI-powered office engine for global manufacturing enterprises, harnessing technological power to make every order transparently visible and every decision confidently informed by data.